Please contact for updated pricing. 800-844-1885

SPECIALTY PRODUCTS

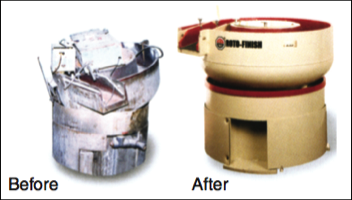

M.C. Finishing sells vibratory soap compound systems, sound covers, vibratory relines, media separators, and vibratory sediment tanks.

SOFT SOUND COVERS

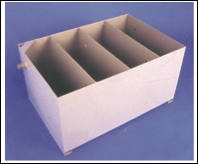

SEPARATION TANKS

COMPOUND PUMP

Mixes compound with water and precisely flows it through your vibratory machine.• Increases Productivity

• Produces Better Finishes

• Eliminates Contamination

SMALL RECIRCULATION SYSTEM

RECIRCULATION PUMP• 7 gal. container

• Pump with bracket

• Vinyl line to machine

RELINE & LINING

Environmentally safe, state-of-the-art, abrasion resistant linings.

Liquid Filtration Systems

Wastewater Engineers, Inc. Presents:

THE RT-65-DB REACTOR

Manual Batch Unit

• Simple, safe, and cost effective method to treat almost any aqueous based wastewater effluent

• Treats a drum of wastewater for less than $1000

• No hazardous treatment by-products

• Guaranteed to meet discharge limits to local sewer

• Compact Design

• Low capital cost Low maintenance, available 1 year, 100% parts replacement warranty

• Ideal for metal working and grinding fluids, vibratory equipment and parts washing fluids, floor cleaning fluids, etc.

Model RT-65-DBN REACTOR

MS-75 Media Separator

Raytech 23-115 MS-75 Media Seperator with Out Screen

The MS-75 Media Separator eliminates tedious hand separating of finished parts from either wet or dry media. It automatically sorts media and parts into two 70-pound capacity tote boxes. A variety of quick change screens are available.Overall machine dimensions are 36" x 20" x 26" at discharge side. Shipping weight 133 pounds; shipping volume 17.94 cubic feet.

Manual Separating Screens

MS-75 Optional Separating Screens:

MS-75 Rinsing & Separating Systems

9/64" Round 23-143

9/32" Round 23-147

5/16 x 1/2" Obround 23-150

3/8" Round 23-167

1/2" Round 23-169

5/8" Round 23-171

3/4" Round 23-175

800-844-1885 for Pricing

Manual Separating Screens

Manual Separating Screens

Screens for manually separating parts from media are 14 1/2 inches in diameter x 2 1/2 inches deep (approximately .25 cubic feet). They are also useful for separating undersize media from us- able media. Made of high impact polymer with integral screen, one- piece molding eliminates problems with parts and media sticking at the joints of two-piece screens. Screens nest for storage.

1/4” Screen 23-205

3/8” Screen 23-207

1/2” Screen 23-209

3/4” Screen 23-211

1” Screen 23-213

Set of 5 (1 of each size) 23-217

Set of 5 with Container 23-222

Container Only (1 cubic foot) 23-224

800-844-1885 for Pricing

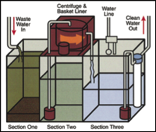

CENTRIFUGAL SYSTEM

ROTO-FUGE

Roto-Fuge wastewater minimization units are designed to work with tumbling barrels, vibratory bowls or tubs and centrifugal finishing systems. The Roto-Fuge generates centrifugal forces up to 2000 times the pull of gravity to remove particles from the waste stream. The particulate remains as sludge in the basket liner and is easily removed. The solution is usually suitable for re-use or may be discharged to drain, if permitted. Optional agitation and flocculation systems generate clear solution for reuse in the finishing process.SMALL RECIRCULATION SYSTEM