Please contact for updated pricing. 800-844-1885

:: POLISHING BUFFING

M.C. Finishing sells Baldor, Burr King/ Hammond, and G&P buffing and polishing lathes, and automated finishing equipment. We also sell buffing lathe hoods, shaft gaurds, backstand idlers, and flex shaft grinders.

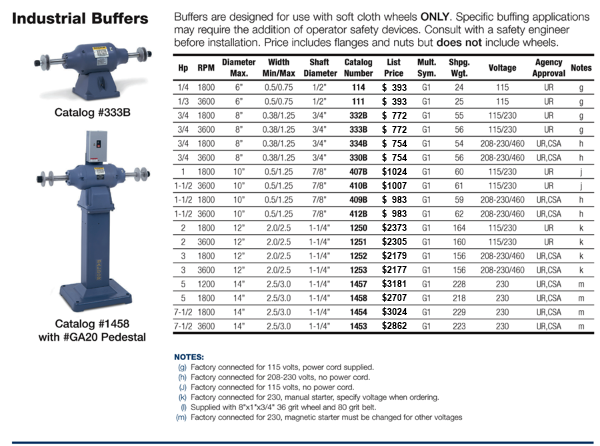

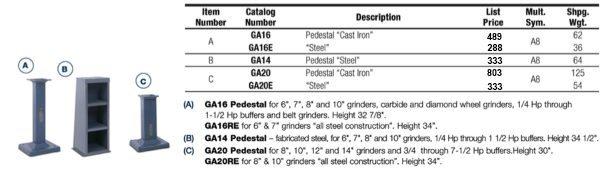

Grinder and Buffer Pedestals

:: GRINDING SANDING POLISHING

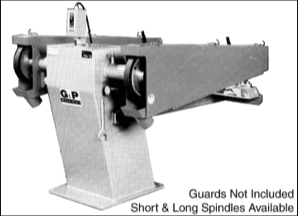

POLISHING AND BUFFING LATHES - SET AND VARIABLE SPINDLE SPEED UP TO 20 HP.

5 HP SINGLE SPEED or WITH VARIABLE SPINDLE7 HP SINGLE SPEED or WITH VARIABLE SPINDLE

10 HP SINGLE SPEED or WITH VARIABLE SPINDLE 800-844-1885 for Pricing

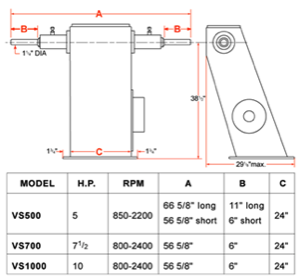

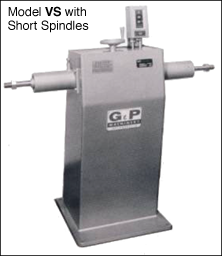

VARIABLE SPEED 5 - 7.5 - 10 HORSEPOWER

SINGLE MOTOR OR DUAL MOTOR MODELS AVAILABLEStandard Features

The VS models are variable speed, the SS models are single speed. Variable speed is accomplished with the use of a variable pitch pully on a sliding motor base and a wide vee belt.

• Electronic tachometer on the VS models.

• Heavy Duty fabricated steel base.

• Spindle lock on each side. (Spindle brake optional).

Magnetic push button starters (NEMA 12 optional).

• 1 1/2" x 6" or 11" long spindles.

Standard Features

The VS models are variable speed, the SS models are single speed. Variable speed is accomplished with the use of a variable pitch pully on a sliding motor base and a wide vee belt.• Electronic tachometer on the VS models.

• Heavy Duty fabricated steel base.

• Spindle lock on each side. (Spindle brake optional).

Magnetic push button starters (NEMA 12 optional).

• 1 1/2" x 6" or 11" long spindles.

Model: VS 500

Single Speed

Model: VS 700

Single Speed

Model: VS 1000

Single Speed

800-844-1885 for Pricing

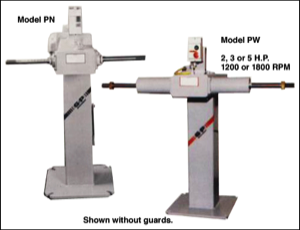

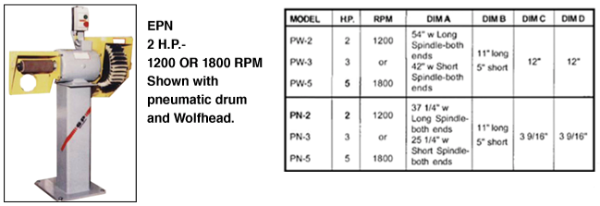

PN & PW SERIES SPINDLE STANDS

MODEL PN (Narrow Type) requires minimum amount of space. Shorter overall spindle length.

MODEL PW (Wide Type) provides maximum spindle clearance. Ideal for applications requiring an operator working each spindle.

:: GUARDS

All polishing and sanding wheels must be guarded to protect the operator. Operating without guards may lead to serious injury. This is stated in a warning sign attached to every machine. G&P offers guards as listed below. Prices for guards will be supplied upon receipt of details of the application.

Designed for mounting to the side of the base, or to the bearing housing_features include hinged door, exhaust outlet, and adjustable scoop.

For use with buffing and polishing wheels. Open bottom also available.

providing easy access for wheel changing.

TYPE B - Door swings open for wheel access.

Both have adjustable scoop, clean out door and exhaust outlet for connection to dust collector.

SERIES SBS (Replaces RBS) SPRING TENSIONED

The SBS series of back stand idlers is an economical method of tensioning an abrasive belt for manual grinding applications. Tension is provided by a torsion spring. The 6" dia. pulley is machined from an aluminum casting, and rotates on sealed ball bearings. The arm and base of the back stand are made of cast iron.

Model SBS-4 for belts of 4" wide or less

Model SBS-6 for belts of 6" wide or less

The SBS series of back stand idlers is an economical method of tensioning an abrasive belt for manual grinding applications. Tension is provided by a torsion spring. The 6" dia. pulley is machined from an aluminum casting, and rotates on sealed ball bearings. The arm and base of the back stand are made of cast iron.

Model SBS-4 for belts of 4" wide or less

Model SBS-6 for belts of 6" wide or less

This accessory, as shown in the picture at the right offers advantages over the typical method of mounting the idlers on the floor.

Because the contact wheel, backstand idlers and guards are all mounted to a support frame that is secured to the base of the machine, it is possible to move or relocate the lathe without remounting or realigning the idlers. The Contact Wheel and Belt Attachment can only be supplied if ordered at the same time as the polishing lathe.

Available with Spring Tensioned idlers or Air Tensioned idlers. The Air Tensioned idlers are recommended for belt speeds of 7500 SFPM and faster due to larger diameter pulleys.

Shown with variable speed 10" x 2" arbors

250-2500 RPM Variable Speed 1-1/2 HP

**The M1001 has optional dust scoops available for purchase.

:: FLEX SHAFT GRINDERS

The A-6s is the Floor Model. This is on the round base with the casters to allow it to roll around.

The Floor Model is most useful if you need to move the machine around the shop or the workpiece.

Model A-6s SINGLE SPEED FLEXIBLE SHAFT MACHINE

Model SCH-6s

The SCH-6s is the Skid Model. This is the type on the the frame with the runners on the bottom and the handle across the top. It is very portable and can be dragged or carried around.

Model A-6sps

The A-6sps is the same as the SCH-6s except that it is does not have the skid frame. The electric motor has a mounting flange on the bottom to allow it to be bolted down or hung overhead from a hook or chain.

All of the options can use the same Flexible Shaft and Handpiece with Adapters.