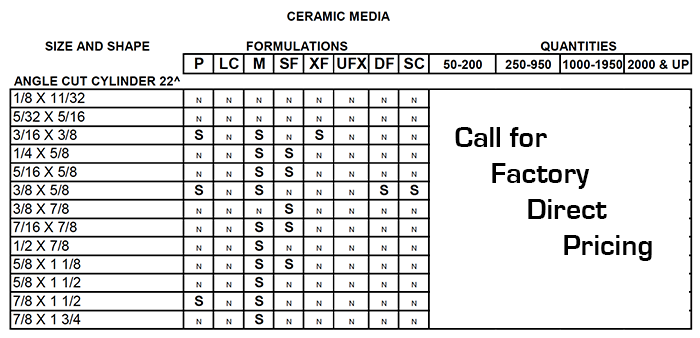

:: CERAMIC MEDIA

CERAMIC MEDIA • FACTORY DIRECT PRICING

Ceramic is the bonding agent, ranging from soft (45 rockwell) on fast cutting medias to hard (65 Rockwell) on burnishing medias. The cutting elements used are generally aluminum oxide or silicon carbide in the grit ranges of 80-220 grit. Burnishing medias do not use cutting elements and the ceramic is off a higher grade harder porcelain. The weight per cubic foot of ceramic is approximately 80 lbs. Smaller media sizes weigh approximately 15% more. There is a light weight ceramic using quartz as an abrasive that weighs 50 lbs/cu. ft. and there is a high density ceramic that weighs 120 lbs/cu.ft.

_____________________________________

_____________________________________

_____________________________________

_____________________________________

P = Polish

LC = Light Cut

M = Medium Cut

FSF = Super Fast

XF = Fast Cut Good Finish

UFX = Ultra Fast Cut

DF = Hight Density Fast Cut

SC = Silicon Carbide

CERAMIC MEDIA • FACTORY DIRECT PRICING

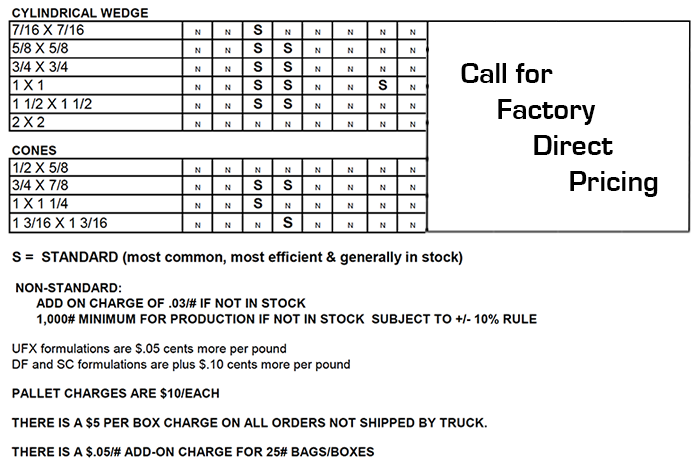

Cylindrical Wedges

Cones

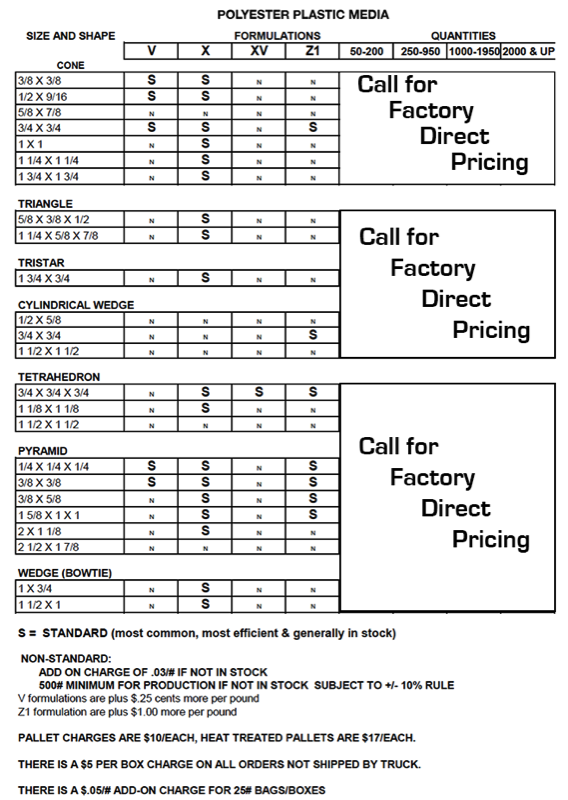

PLASTIC MEDIA • FACTORY DIRECT PRICING

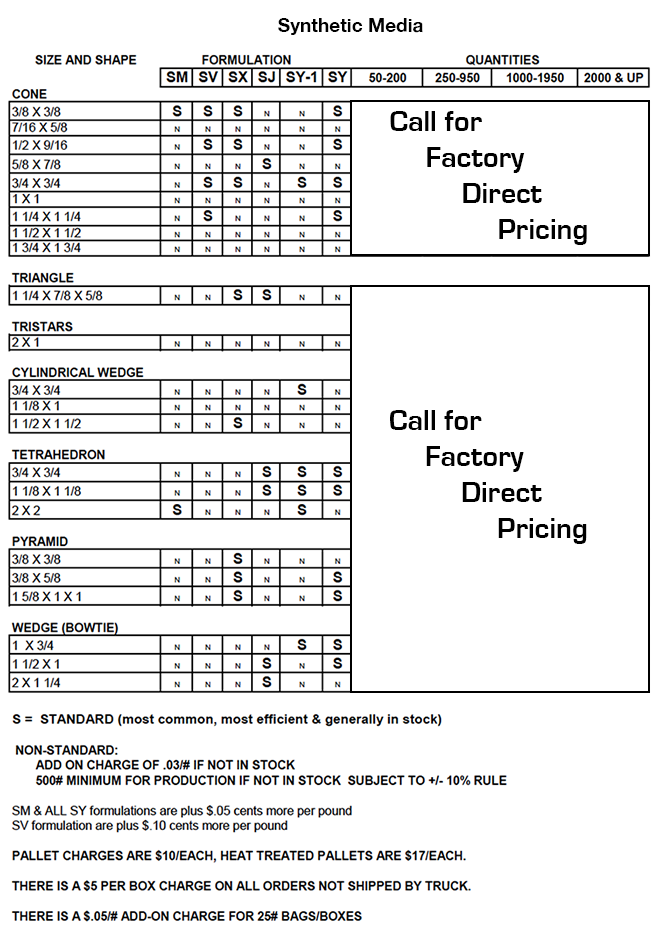

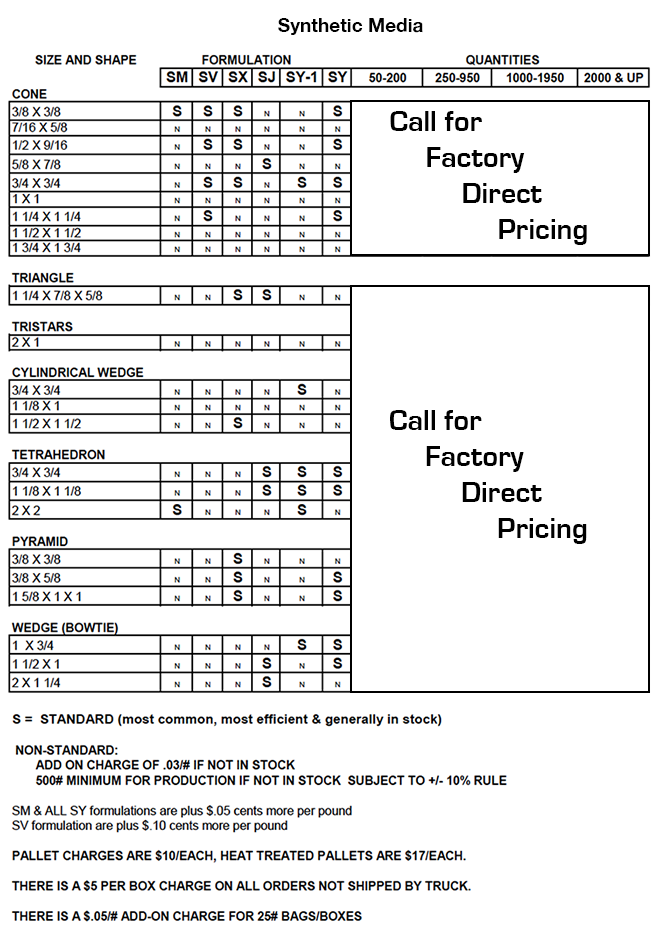

SYNTHETIC PLASTIC MEDIA

Benefits of Synthetic Media

• Eliminates foaming as well as the residue plaguing polyester media formulations.

• Has a 20% to 45% lower Bulk Density than Polyester and Ceramic Media offering a Greater Volume per pound and yielding a lower working cost

• Lesser weight Per Cubic Ft. Synthetic will reduce surface hammering and impingement:

: : Synthetic 55/lbs Cu. Ft. : : Polyester 65/lbs. Cu. Ft. : : Ceramic 85/lbs. Cu Ft.

• Offers extremely Fine Finishes.( Ideal for medical, Dental, Aerospace etc.....)

• The effluent from Vibra Finish Synthetic Media separates quickly in a matter of hours compared to days for Polyester Media.

• Vibra Finish Synthetic Media is water based, cost effective and easily treated material for removal in waste water systems.

• Quick settling of solids makes closed- loop waste water systems practical, affordable offering a considerable water cost saving for continual use.

Benefits of Synthetic Media

• Eliminates foaming as well as the residue plaguing polyester media formulations.

• Has a 20% to 45% lower Bulk Density than Polyester and Ceramic Media offering a Greater Volume per pound and yielding a lower working cost

• Lesser weight Per Cubic Ft. Synthetic will reduce surface hammering and impingement:

: : Synthetic 55/lbs Cu. Ft. : : Polyester 65/lbs. Cu. Ft. : : Ceramic 85/lbs. Cu Ft.

• Offers extremely Fine Finishes.( Ideal for medical, Dental, Aerospace etc.....)

• The effluent from Vibra Finish Synthetic Media separates quickly in a matter of hours compared to days for Polyester Media.

• Vibra Finish Synthetic Media is water based, cost effective and easily treated material for removal in waste water systems.

• Quick settling of solids makes closed- loop waste water systems practical, affordable offering a considerable water cost saving for continual use.

Cone

Cones are designed so the unique shape enables them to deburr into remote areas without lodging. This shape will wear extremely well because there are not sharp edges.

Cones are designed so the unique shape enables them to deburr into remote areas without lodging. This shape will wear extremely well because there are not sharp edges.

Cylindrical Wedge

Cylindrical Wedge combines the strong points of triangles and cylinders to penetrate into corners, slots and angles.

Cylindrical Wedge combines the strong points of triangles and cylinders to penetrate into corners, slots and angles.

Wedge

Wedge is a uniquely designed media that eliminates many lodging problems, while its configuration will reach hard to finish corners, slots and angles. Sharpens as it wears.

Wedge is a uniquely designed media that eliminates many lodging problems, while its configuration will reach hard to finish corners, slots and angles. Sharpens as it wears.

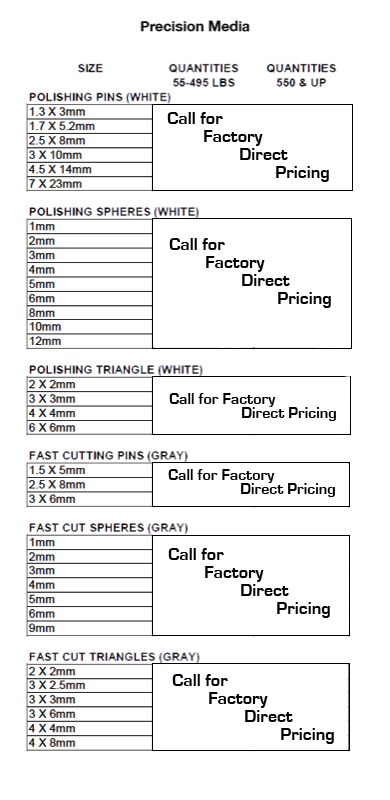

POLISHING & SPECIAL PROCESS MEDIA • FACTORY DIRECT PRICING

Precision Polishing & Cutting Media

Polishing Pins (White) / Polishing Spheres (White) / Polishing Triangle / FastCutting Pins (Gray) / Fast Cut Spheres (Gray) / Fast Cut Triangles (Gray)

TECHNICAL INFORMATION

Special Process Media

Random Medias

Sand, river rock or man made sintered ceramics for burnishing and aluminum oxide nuggets for fast cutting are examples of random medias. They are screened for size, but are random in shape allowing processing many areas of part.

Dry Process Media

Corn cob, walnut shells, wood pegs and some preformed composite medias are used to run dry. Running dry presents a challenge without the water cushioning or cleaning the mass. Dry medias carry or are impregnated with polishing powders or paste. They are primarly used in brightening parts and can be run in all types of finishing equipment.

Steel Media

Is a product cold formed from wire, heat treated and polished. They are available in many shapes. Steel Media have precise measurements and wears very slowly with service life up to 10-20,000 hrs. they are available in carbon and stainless alloys. The media weighs approx. 300 lbs a cubic foot, so machines have to be built especially to handle the weight. The applications are part of burnishing, peening for strength, and light deburring without lodging.