Please contact for updated pricing. 800-844-1885

:: PRO-FINISH CABINETS

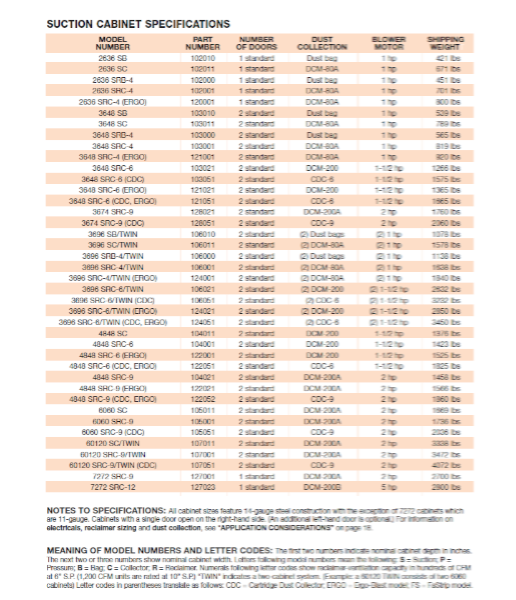

SUCTION CABINETS

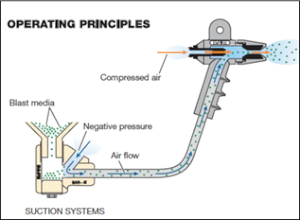

Pro-Finish suction cabinets cost less and are simpler than pressure cabinets. They also blast continuously without the need to stop for media refills, and they simplify the use of multiple nozzles. The results are usually comparable to those achieved with a pressure system although production rates are not as high. When initial cost and maintenance are primary concerns, the suction system is a good choice.

Blower located on clean side of dust collector prolongs fan life. Rigid double-panel door delivers extended service life and reduces leakage; flush construction eliminates media spills. Tunable reclaimer reduces media loss, cuts operating costs and improves finishing results. Self-adjusting door latch assures continued tight sealing as gasket ages. Kleensweep™ system directs airflow across window to prevent dust buildup and improve visibility.

Model: SRC 3648

800-844-1885 for Pricing

(Suction with reclaimer and collector)

Model: SRB 2636

800-844-1885 for Pricing

(Suction with reclaimer and bag)

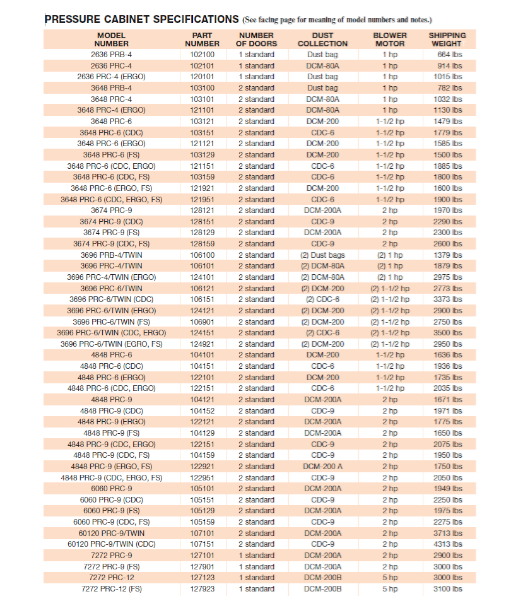

PRESSURE CABINETS

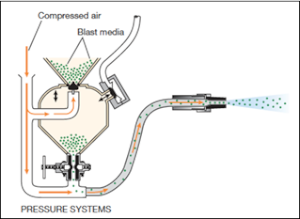

Because pressure cabinets deliver blast media at higher velocities than suction systems, a Pro-Finish pressure cabinet is ideal for turning out work fast. In many applications, these pressure cabinets will perform jobs four-times faster than suction systems. In Addition, they use compressed air more efficiently and provide more precise blasting control at both high and low operating pressures. For really demanding tasks, like removing tight mills scale or finishing hard-to-reach surfaces, a pressure system is normally the only practical choice.

Large safety-glass window is designed for greater visibility and quick, easy replacement.

Easily accessible pneumatic controls, which include a door safety switch (U.S. pat. 4,505,077) to prevent accidental blasting, provide greater reliability than electric solenoid systems. General-purpose filter prevents residual moisture and oil from contaminating abrasives and prolongs media life.

Model: PRC 3648

800-844-1885 for Pricing

(Pressure with reclaimer and collector)

Model: PRB 3648

800-844-1885 for Pricing

(Pressure with reclaimer and bag)

WHY YOU SHOULD CHOOSE

A PRO-FINISH® SYSTEM

If your operations involve cleaning with chemicals, acid etching or dipping, liquid honing, wire brushing, sanding, de burring, grinding or peening, odds are a Pro-Finish system will save you time and money.

• These cabinet systems, designed for non-stop blasting, increase production rates because blasting is faster than other manual methods.

• Their versatility enables you to perform multiple tasks, ranging from blending surface flaws to removing foreign matter, such as carbon from pistons, without affecting tolerances. By simply varying air pressure and blast media, you can clean or peen and do a lot in between.

• Modular design, including many standard factory options, lets you select a system that’s just right for you—without paying for features and accessories you don’t need. Pro-Finish also gives you the choice of a suction or pressure blast system.

• Blasting eliminates the environmental hazards associated with chemical finishing because most modern blast media are non-caustic and non-toxic. Plus, Pro- Finish systems put the emphasis on safety in mechanical ways with features such as blasting interlocks on cabinet doors, rounded corners on safety-glass viewing windows and guards on sharp floor edges, just to list a few.

PRO-FINISH MEDIA RECLAIMERS

Media reclamation can be one of the most critical aspects of air-blasting processes. In addition to media costs, reclaimer performance affects operating speed and quality. Failure to remove dust and fines has an adverse effect on consistency and productivity. If oversized particles are returned to the blast system, for example, clogging and/or inconsistent results often occur. Pro-Finish reclaimers provide precise control of media recycling. These reclaimers can be adjusted to control the recovery of fine, medium or coarse working materials while removing unwanted particles from the blasting process. As a result, you enjoy reduced media costs as well as consistent, high-quality results. All Pro-Finish reclaimers deliver 99% efficiency, include a screen to prevent over-sized particles from clogging, provide an easy-open access door for quick cleaning and filling, and feature 12-gauge construction for extended service life.

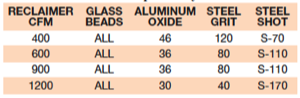

Media/Reclaimer Compatibility

Chart shows the maximum media sizes recoverable with single-gun/nozzle systems. Multiple guns, larger nozzles, operation at altitudes above 5000 feet, or use of a 50-Hz electrical supply may require a larger reclaimer and dust-collector blower. Larger sizes may be used. Consult factory.

PRO-FINISH DUST COLLECTORS

Available in both bag- and cartridge-type designs, Pro-Finish dust collectors improve working conditions while reducing maintenance and operating costs. By capturing 99% of all particles one micron or larger, these efficient dust collectors permit filtered air to be recirculated into the plant, thus providing significant savings on heating and air conditioning.Other features of Pro-Finish dust collectors include:

• Fan blade on clean-air side for long life

• 14-gauge, reinforced construction

• Raised clean-out opening for fast waste removal

• Top-clean air discharge for operator comfort

• Easy push-button control for thorough cleaning

• Cartridge models for simplified maintenance

• Fan blade on clean-air side for long life

• 14-gauge, reinforced construction

• Raised clean-out opening for fast waste removal

• Top-clean air discharge for operator comfort

• Easy push-button control for thorough cleaning

• Cartridge models for simplified maintenance

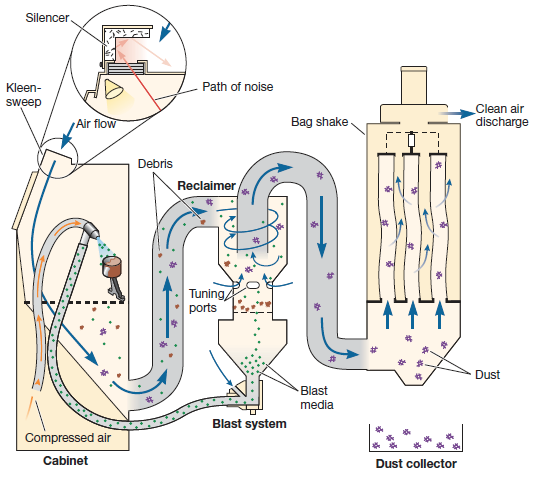

RECLAIMER OPERATING PRINCIPLES

All Pro-Finish media reclaimers are tunable. By adjusting a fine-tuning band on the reclaimer, the amount of air introduced into the system can be controlled to assure precise separation of functional media from dust and other unwanted debris. As spent media, dust and debris are pulled by air flow to the reclaimer inlet, incoming air and media spiral in a downward vortex, throwing larger particles against the outer reclaimer wall. An air stream forms an upward counter vortex through the center tube, which carries out dust while heavier particles drop into the storage hopper below for reuse. A screen catches any oversized debris. Dust and undersized debris are drawn from the reclaimer into the bottom of the dust collector. Sudden expansion forces heavier dust particles to the bottom. Remaining fine dust is pulled to the surface of the dust filters. Clean air can then be discharged to the work area.

NOTE: The CFM of all Pro-Finish reclaimers is rated at nominal static working pressure of 6” water, with the exception of the 1200 CFM model, rated at 10” static pressure. Competitive units may appear to achieve higher CFM due to ratings based on inadequate working static pressure.

:: PROFORMER PREMIUM SPECIALTY CABINET

PROFORMER™

Hard Working, Simple to Hook Up and Easy to Move

OPTIONAL EQUIPMENT Reclaimer, pressure vessel (pressure systems only) and dust collector are all contained in one, easily transportable unit.

Simple, pneumatic controls are extremely reliable.

Multi-function filter prevents oil, water and particles from contaminating media.

Fork-lift slots make the cabinet easy to move.

Minihelic gauge shows the pressure differential across filtration surfaces, promoting the operator to pulse-clean dust-collector cartridges.

Kleensweep™ System directs airflow across the window for improved visibility.

Safety-glass window improves visibility and easy to replace.

Safety switch prevents accidental blasting when doors are open; complies with OSHA requirements.

Media-load station inside cabinet door (see back) simplifies replenishment of abrasives

Model: PN 111013, 3642 Suction

800-844-1885 for Pricing

Model: PN 111023, 3642 Pressure

800-844-1885 for Pricing

Model: PN 111033, 4652 Suction

800-844-1885 for Pricing

Model: PN 111043, Pressure

800-844-1885 for Pricing

OPTIONAL EQUIPMENT

Turntables speed up parts handling and open avenues to automation.

Fixed gun holder frees operator to manipulate parts.

“Two-in-One” basket turns Pro- Finish cabinet into a dual-purpose machine capable of finishing small parts

:: PRO-FINISH CABINET OPTIONS

ERGO-BLAST CABINETS

Empire offers a number of standard Pro-Finish variations for specialized air-blasting jobs. Ergo-Blast systems, for instance, increase productivity by improving operator performance during extended periods of continuous blasting. These cabinets are ergonomically designed for sit-down operation and include other features to reduce fatigue. As a result, machine operators concentrate on the job at hand when working for hours on repetitive tasks rather than trying to find the best position to relieve a sore back. By removing everyday distractions, Ergo- Blast cabinets maximize production.

FaStrip® CABINETS

Pro-Finish FaStrip cabinets are specifically designed for use with low-density media, such as plastics, that provide fast coverage without eroding substrates. Paint stripping, for example, can be performed quickly and economically without the use of hazardous chemicals. FaStrip cabinets deliver plastic or organic media from a large venturi nozzle coupled to a grounded, flexible blast hose. A large, vibrating screen within the reclaimer and Empire’s exclusive automatic Sure-Flo media regulator, working in tandem with the MG-78 CR exhaust valve, keeps light media flowing smoothly. A magnetic separator is also included in the system to extract ferrous particles that can damage delicate substrates.

Ergo-Blast Features

• Knee-hole indentation for sitting operation

• Elevated foot rest for treadle control

• Elevated, padded arm rest that pivots

• Top-entry nozzle to take weight off operator’s hand

• Cabinet sound attenuator

• Door trays to catch stray dust

• Available in FaStrip models

• Knee-hole indentation for sitting operation

• Elevated foot rest for treadle control

• Elevated, padded arm rest that pivots

• Top-entry nozzle to take weight off operator’s hand

• Cabinet sound attenuator

• Door trays to catch stray dust

• Available in FaStrip models

FaStrip Features

• Automatic Sure-Flo saves air, smooths media flow

• MG-78 CR exhaust valve improves media control

• Magnetic separator removes ferrous particles

• Vibrating reclaimer screen removes large debris

• Available in Ergo-Blast configurations

• Automatic Sure-Flo saves air, smooths media flow

• MG-78 CR exhaust valve improves media control

• Magnetic separator removes ferrous particles

• Vibrating reclaimer screen removes large debris

• Available in Ergo-Blast configurations

FaStrip cabinets remove old coatings quickly without damaging delicate substrates.

Magnetic separator extracts ferrous debris and can be removed easily for cleaning.

ADDITIONAL CABINET OPTIONS

Fan sound attenuator on Pro-Finish dust collectors reduces noise levels below 85 db (A) in accordance with OSHA standards.

Vertical-lift doors work smoothly and seal tightly to prevent media leaks. Plus, they are the safest in the industry.

Turntables speed up parts handling and open avenues to automation.

Fine-tuning controls let operator adjust air/grit ratio from front of cabinet for optimum results.

Fixed-nozzle holder frees operator to manipulate parts.

Rubber curtains, available in white to enhance visibility, protect the cabinet interior and are easy to replace.

ADDITIONAL CABINET OPTIONS

OPPORTUNITIES TO AUTOMATE

Powered movement of blast nozzles and/or workpieces automates air-blasting operations to varying degrees. For instance, using a powered turntable in combination with oscillating nozzles makes many blast-finishing processes virtually automatic when a timer package is added to control duration and on/off functions. Some techniques for automating Pro-Finish cabinets—easily and economically—are described below.

Fixed gun holder frees operator to manipulate parts.

4.5-cubic-foot media storage hopper provides a large supply of abrasives to support up to four blast guns.

Precision reset timer controls blast duration and helps deliver consistent results.

"Two-in-One" basket turns Pro-Finish cabinet into a dual-purpose machine capable of finishing small parts automatically.