Please contact for updated pricing. 800-844-1885

:: AUTOMATED BLASTERS

M.C. Finishing sells Empire basket blasters, Robot blasters, rotary head turntable blasters, and in-line conveyor automated blasters.

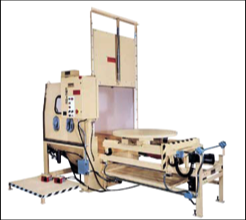

IN-LINE 885 CONVEYOR

FINISH PARTSIN-LINE ECONOMICALLY

Conveyor assembly with adjustable part guides can be removed easily for maintenance. Variable belt speed control conveys parts at rates of 11 to 10 feet per minute.

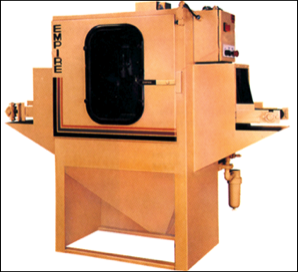

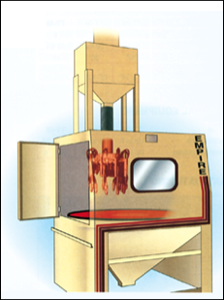

ROTARY-HEAD MACHINES FOR BATCH

PROCESSING

Empire’s PF-6060-RS (with 48” turnable) and PF-7272-RS (with 60” turntable) provide an economical means for processing workpieces in batches. These machines, equipped with rotating blast guns that provide even coverage, are ideal for parts requiring long blast cycles. The operator simply loads work pieces onto the turntable, sets the timer, starts the machine and returns when blasting is completed. Blast-head and table-rotation speeds are both variable.

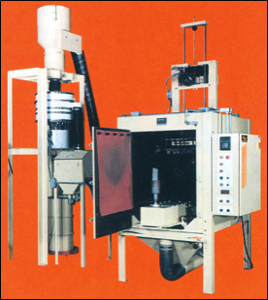

AUTOMATED SHOT-PEENING MACHINES

Glass-bead system for peening jet-engine turbine blades incorporates vertically oscillating nozzles, a vibratory bead classifier, and one rotating work station.

FLAT SHEET PROCESSING

This pass-through cabinet simplifies the handling and finishing of metal or glass plates. Special features include a gasketed entrance/exit slot between the cabinet’s double doors in addition to interior part guides that facilitate material handling.

PIPE FINISHING

Modified cabinets with openings on both sides provide a space-saving alternative to larger cabinets. Designed for finishing pipe, the unit shown above has dual-baffle plates in the entrance and exit vestibules to contain dust and media. A powered system can be added to feed and roll parts automatically.

MODIFIED PRO-FINISH CABINETS

To speed finishing of very long workpieces, Empire can supply a dual-cabinet system. The unit shown includes a center expander with its own glove set and foottreadle control, which operates one of the system’s two blast guns. Cabinet controls are independent, enabling two operators to work on a single piece at the same time.

MODIFIED PRO-FINISH CABINETS

The Empire cabinet shown above provides a small glimpse of our versatility in modifying cabinets to meet specialized production requirements. With a vertical-lift door, a powered turntable and a hands-on work station, this unit integrates manual control with automation to exploit the best of both worlds.

AUTOMATED AIRLESS WHEEL BLASTING

BASKET AND CONTINUOUS BELT BLASTERS

TABLE BLASTERS

APPLICATION

• Steel and Stainless Steel Media

• Small Part Automation

• Castings

• Large Weldments

• Structural, IBeams

• Steel and Stainless Steel Media

• Small Part Automation

• Castings

• Large Weldments

• Structural, IBeams

INLINE CONVEYOR BLASTER STRUCTURAL BLASTING

Propane Tank Blasting

Structural Pass Thru Blaster

LS Industries - Monorail Pass Through Blaster

The Monorail Blaster model LS MRB48126 is a custom built 12-wheel shot blaster for large-scale manufacturing. The cabinet is built with a slot for the monorail conveyor system. The blast cabinet is 34' long with extended vestibules. The shot blast system is integrated with a paint line and cure oven.

The Monorail Blaster model LS MRB48126 is a custom built 12-wheel shot blaster for large-scale manufacturing. The cabinet is built with a slot for the monorail conveyor system. The blast cabinet is 34' long with extended vestibules. The shot blast system is integrated with a paint line and cure oven.

OD BLASTER

OD BLASTER

ID BLASTER

:: PRO-FINISH AUTOMATED

This multi-purpose shot-peening system includes an ID blast lance to peen recessed surfaces on parts, a powered loading cart, independently adjustable pressure nozzles, a shot classifier, and a combination of vertical/horizontal oscillating blast nozzles. Operating parameters are adjustable, making this machine ideal for job-shop work.

Versatile peening machine enabled a repair center for jet-engine parts to expand its business into the areas of disc and hub rebuilds. In addition to peening recessed surfaces, the unit processes many different size parts ranging up to thirty inches in diameter.

BEST-EQUIPPED TEST LAB AND DEMONSTRATION CENTER IN THE WORLD

Our test lab and demonstration center in Langhorne, PA, is the world’s largest. It enables us to sample blast parts, as well as demonstrate standard approaches to automated blasting. Machines shown, which should interest prospective users concerned about the higher equipment costs associated with custom engineering, include a standard in-line machine (Model: IL-885), one of our indexing turntables (Model: TT-36-S), a cabinet equipped with a rotary blast head (Model: PF-6060-RS), and a batch-processing basket blaster (Model: BB4-3K).

CONTINUOUS PROCESSING

Empire offers turntable and in-line machines for continuous processing. These systems can be loaded and unloaded manually, equipped with robotic arms or designed as an integral part of the production line. Our continuous turntable machines come in four standard models with table diameters ranging from 36 inches up to 108 inches. Larger units are available with two rotary blast heads. The heads can be oriented to perform separate functions, such as blasting the interior and exterior of parts at the same time. Standard features include a rubber cabinet lining and a urethane coating on the turntable for extended service life.

The indexing turntable shown above blasts a variety of cooking containers, including quart pans, 12” frying skillets, and 16” Dutch ovens. This six-station turntable, with a dual-chamber, continuous-action pressure vessel, supports six blast nozzles, which finish two parts at a time within this automated system. A vertical door, working internally, separates blast and blow-off stations. Pneumatic lines power the movements of exterior and internal doors. The machine’s controls interface smoothly with pick-and place or robotic loading devices.

:: AUTOMATED BASKET BLASTING Small Part Blasters

BBO BASKET BLASTERS

BASKET BLASTER9”x9” 1/16” perforated metal, removable

CONSTRUCTION

All welded, 16 gauge

MOTOR

115V, 60 Hz. 1 Phase, 1/100hp, 7RPM, fixed

ELECTRICTIMER

60 minute maximum cycle

DUST COLLECTOR

BBO-1: dry filter dust bag

BBO-2: DC-16 with blower and cartridge

filter, 7 amps.

LOAD CAPACITY

15 lbs. max on all models

MODEL

Outside Dimensions (DxWxH)

Cabinet with reclaimer

Dust Collector

Basket

Size

Door Opening

Capacity

Perforations

Standard Non-Coated

Optional Coated

Optional non-coated

Blast Guns Number

Size

Type

Oscillation

Compressed air/60 PSI

Outside Dimensions (DxWxH)

Cabinet with reclaimer

Dust Collector

Basket

Size

Door Opening

Capacity

Perforations

Standard Non-Coated

Optional Coated

Optional non-coated

Blast Guns Number

Size

Type

Oscillation

Compressed air/60 PSI

BB2-3K

(DxWxH)

61x56x74”

26x22x98

30”xDx16”L

10”Wx11”H

300 lbs. 1-1/2 cu. ft.

5/16” dia

5/16” dia or less

1/8” dia

2

5/16 w/5/32” Jet

Di-Carb

No

54 SCFM

(DxWxH)

61x56x74”

26x22x98

30”xDx16”L

10”Wx11”H

300 lbs. 1-1/2 cu. ft.

5/16” dia

5/16” dia or less

1/8” dia

2

5/16 w/5/32” Jet

Di-Carb

No

54 SCFM

BB4-3K

(DxWxH)

*61x87x74”

39x34x105”

30”xDx16”L

24”Wx11”H

350 lbs. 1-1/2 cu. ft.

5/16” dia

5/16” dia or less

1/8” dia

3

5/16 w/5/32” Jet

Di-Carb

Yes, all pneumatic

81 SCFM

(DxWxH)

*61x87x74”

39x34x105”

30”xDx16”L

24”Wx11”H

350 lbs. 1-1/2 cu. ft.

5/16” dia

5/16” dia or less

1/8” dia

3

5/16 w/5/32” Jet

Di-Carb

Yes, all pneumatic

81 SCFM

12” BASKET BLASTER

Large Front Swing Door Opening

12” Diameter Coated Removable Basket

2 – 25 CFM Blast Nozzles for a Quick Even Processing

On/Off timer

Quick Change Media Hopper Door

400 CFM Dust Collection