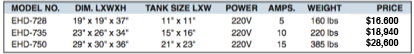

Please contact for updated pricing. 800-844-1885

HIGH ENERGY SPECIALTY SYSTEMS

SPECIALTY HIGH ENERGY SYSTEMS

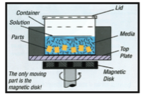

Small Part Deburring

Powerful Magnetic force moves media, solution and parts in circular motion.Applications

• Medical parts - swiss turned

• Drilled or threaded parts

• Machined or stamped parts

• Internal burrs and whiskers

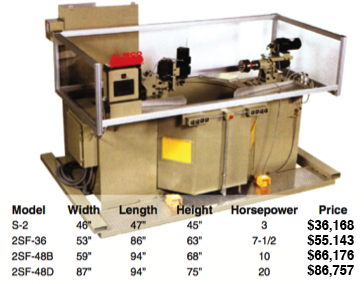

SPINDLE FINISHING MACHINES

Working Hand in Hand For a Great Finish - Almco Spindle Machines and Robotics

Abrasive slurry moving at speeds up to 1000 surface feet per minute processes large parts or clusters of small parts on spindle mounted chucks. Centrifugal force spins the selected finishing media into a “form fitting grinding wheel” while slow rotation of parts in the mass assures uniform deburring and finishing of all surfaces. Delivers precision finishing of gears, crankshafts, bearing cages, splined shafts, pump rotors, jet compressor discs, jet blades and other complex parts.

ECD-1001

•Deburring of Medical, Aerospace, and Hydraulic parts requiring a clean, repeatable, burr-free finish •55 V DC 10A continuous power •Proprietary “ARC Quenching Circuitry” eliminates scrap parts due to probe short circuit •Custom probe designs (workpiece specific) •Deburring of cross holes, intersecting features, and deep hole locations where conventional methods failElectro chemical deburring offers selective material removal for hard-to-get-at burrs.

•Process removes burrs preferentially, minimal effect on parent material •Easy to use, repeatable results, low costWill not harm parts

•Non-contact deburring •No secondary burrs createdHow it works

•Electrode is placed near the burr •Electrolyte solution floods the area •A small DC current flows from the part to the electrode •Burrs are dissolved and flushed away

Electro chemical deburring offers selective

material removal for hard-to-get-at burrs.

SF STREAM FINISHING

SF – A new Machine Generation

SF machines are available in a wide variety of models, which means that almost all workpiece require-

ments can be accommodated. For example, the machines are available with five basic drum sizes:

E 330 mm for up to 1 workpiece holder, for workpieces measuring Ø 6 x 60 mm max.

E 780 mm for up to 2 workpiece holders, for workpieces measuring 100 x 200 mm max.

E 1050 mm for up to 5 workpiece holders 400 x 400 mm

E 1450 mm for up to 6 workpiece holders 400 x 400 mm

E 2000 mm for up to 6 workpiece holders 200 x 200 mm max.