Please contact for updated pricing. 800-844-1885

:: BLAST-ROOM FACILITY

M.C. Finishing sells Empire pre-assembled and field erected blast rooms. We can accommodate any size part. We build rooms with sweep-in, partial, and full floor recovery.

If you have special requirements, Empire’s sales and engineering staff will work with you to develop a top-quality system to fit your specific needs.With more than 50 years’ experience producing air-blast equipment, we have the technical and manufacturing resources to do the job right, and provide turnkey installation if desired. Empire offers two types of blast-room enclosures (Pre-assembled and Field Erected) in a wide variety of configurations. Once you’ve decided which type is best for your operation, our engineering department will design your room using proven Empire components. This field-tested equipment includes; pneumatic recovery systems; bucket elevators; cyclonic and air-wash reclaimers; drum separators; sweep and shovel chutes; vibratory, pneumatic and screw floors; ventilation systems; pressure vessels; blast controls; and safety equipment – everything to assure your Empire blast room performs efficiently, safely and smoothly.

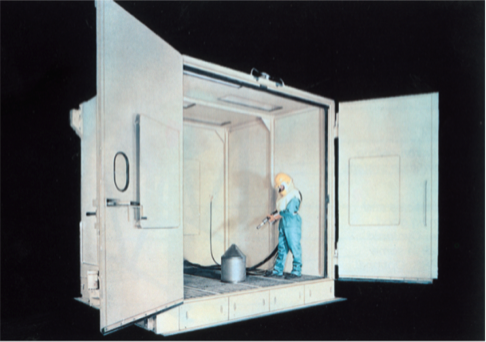

PRE-ASSEMBLED BLAST ROOM

Pre-assembled blast rooms are available with many options in a variety of enclosure sizes. These enclosures feature #10-gauge wall/ceiling panels and fully welded construction. Package rooms can be installed quickly. They are normally up and running within a day.

Quality Engineered for Environmental Safety and BLAST ROOMS Improved Productivity

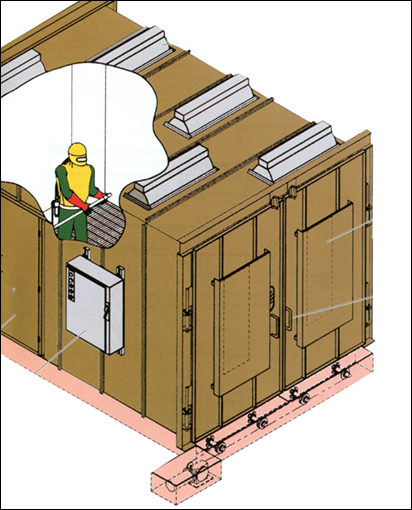

FIELD-ERECTED BLAST ROOM

Field-erected room enclosures are available in dimension adaptable to almost any requirement. Rugged, #10 gauge wall and ceiling panels can be bolted or welded together. Advantages include: lower shipping costs, greater design flexibility and enhanced compatibility with your specific space and production requirements.

MANY FIELD-OPTIONS

Fluorescent lighting on ceiling and sidewalls, protected by clear lexan panels, provides excellent illumination and easy maintenance from outside the blast room.

Air-inlets assure proper cross-draft ventilation.

Empire offers a wide range of media recovery options, including: screw floors, vibratory floors, sweep chutes and pneumatic-recovery troughs.

Overhead monorail or trolley

Turntables and work carts

Multiple blast outlets

Sweep/shovel-chute

Sweep/shovel-chute recovery system provides an economical method for recycling media through the air-wash system.

Sweep/shovel-chute

Full-floor systems.

U”-shaped design

“U”-shaped design collects from both sides so less time is spent on sweep in.

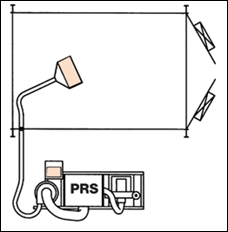

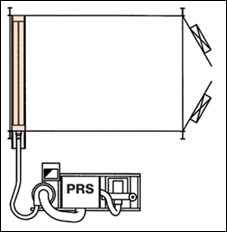

PRS BLAST & RECOVERY SYSTEMS

THE RIGHT RECOVERY SYSTEM FOR YOUR PRODUCTION NEEDS

PRS system offers an economical alternative to a full blast room for limited-use operators. In addition to pneumatically collecting media, the unit recycles and cleans abrasives through a cyclonic reclaimer attached to a media-filtration system.

Media recovery hopper can be moved around work area for easy media retrieval.

A floor trough permits easy sweep-in delivery to the pneumatic-recovery system.