Please contact for updated pricing. 800-844-1885

CENTRIFUGAL BARREL - HIGH ENERGY

ROTO-CENTRIFUGAL BARREL

1-10 Cu. Ft. Capacity Semi & Automated Standard Machines Available

HOW IT WORKSWith a high energy centrifugal machine, your parts are placed inside closed barrels along with media, compound, and water. The RCB series machines have four (4) barrels evenly mounted opposite direction giving you a high energy sliding action inside the compartment resulting in a uniform part roll during processing and a uniform finish on your parts.

• Small Part Processing

• Small Media Processes

• Super Finishes

• Dry & Wet Process

• Fixtured Parts

Model RCB-1

Model HZ-120 shown with optional media separator

HZ-12 for smaller finishing equipment

HZ-12 for smaller finishing equipment

CENTRIFUGAL BARREL HIGH ENERGY

HIGH SPEED AND VERSATILE FOR ANY FINISHING APPLICATION

HOW IT WORKS

MFI’s HZ Series Centrifugal Barrel finishing machines provide the most economical, high-speed finishing available. HZ machines operate on the “ferris wheel” principle with a 1:1 ratio of barrel rotation to turret rotation. Four barrels are mounted at the periphery of a large turret. Each barrel is loaded to approximately 50 - 80% full, with media, parts, and water. During operation, rotation of the turret creates force on the media and parts inside each barrel. This force reduces the cycle time needed to complete the finishing of the parts by up to a factor of 30 over conventional vibratory and barrel finishing.

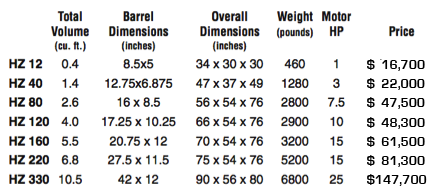

SERIES HZ SPECIFICATIONS