Please contact for updated pricing. 800-844-1885

:: BLASTING MEDIA

FACTORY DIRECT PRICING ON BLASTING MEDIA

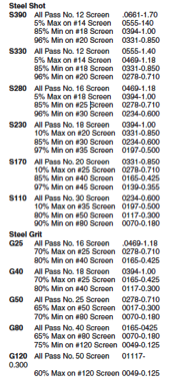

BLASTITE® BT

BLASTITE® BT is a tough, medium density, virgin, fused brown aluminum oxide abrasive.BLASTITE® BT is designed for the pressure blasting of materials of almost every type, including glass, granite, marble and ceramic. It is also used for the preparation of surfaces prior to painting or bonding; as well as for light deburring, scale removal, and the generation of matte finishes. BLASTITE® BT is closely sized.

NIAGARA BLAST®

• group graded virgin brown aluminum oxide

• used in blasting applications where size control is less critical DURALUM® SPECIALWHITE AluminumOxide

• more closely graded, high purity, white aluminum oxide

• composed of sharp, friable grains, specially treated for removal of iron

• premium material for use where surface contamination is unacceptable

• used in applications such as cleaning and deburring electrical circuit boards and medical components

CARBOREX® RA

• extremely hard, sharp silicon carbide grain that is more friable

than aluminum oxide

• used to blast extremely hard materials

TYPICAL BLASTITE® APPLICATIONS

• cleaning of investment castings

• scale removal in steam turbines

• surface preparation for thermal spray coatings

• rust removal

• hard oxide removal (titanium, zirconium, etc.)

• mill scale removal

• heat treat scale removal

• glass etching or frosting

• monument lettering

• aircraft engine overhaul

• matte finishing

• surface preparation

• durability (up to 20 passes)

• no free crystalline silica (unlike sand and many naturally occurring minerals)

BLASTITE® BT is a tough, medium density, virgin, fused brown aluminum oxide abrasive.BLASTITE® BT is designed for the pressure blasting of materials of almost every type, including glass, granite, marble and ceramic. It is also used for the preparation of surfaces prior to painting or bonding; as well as for light deburring, scale removal, and the generation of matte finishes. BLASTITE® BT is closely sized.

NIAGARA BLAST®

• group graded virgin brown aluminum oxide

• used in blasting applications where size control is less critical DURALUM® SPECIALWHITE AluminumOxide

• more closely graded, high purity, white aluminum oxide

• composed of sharp, friable grains, specially treated for removal of iron

• premium material for use where surface contamination is unacceptable

• used in applications such as cleaning and deburring electrical circuit boards and medical components

CARBOREX® RA

• extremely hard, sharp silicon carbide grain that is more friable

than aluminum oxide

• used to blast extremely hard materials

TYPICAL BLASTITE® APPLICATIONS

• cleaning of investment castings

• scale removal in steam turbines

• surface preparation for thermal spray coatings

• rust removal

• hard oxide removal (titanium, zirconium, etc.)

• mill scale removal

• heat treat scale removal

• glass etching or frosting

• monument lettering

• aircraft engine overhaul

• matte finishing

• surface preparation

• durability (up to 20 passes)

• no free crystalline silica (unlike sand and many naturally occurring minerals)

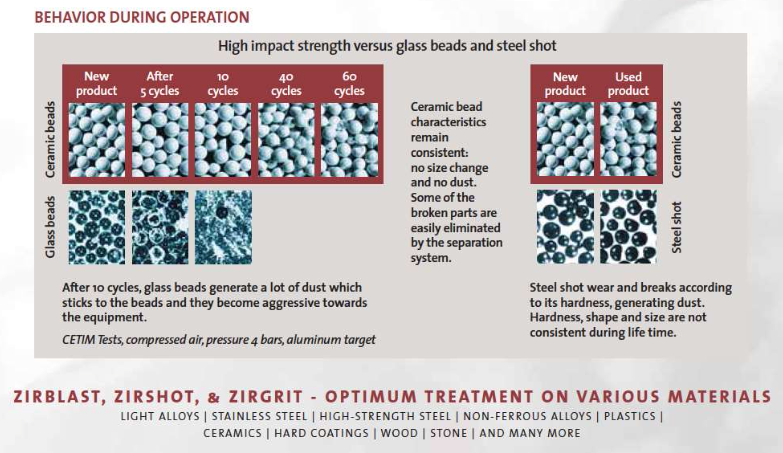

CERAMIC BLASTING MEDIA

ZIRBLAST® ZIRSHOT® ZIRGRIT®

MEET YOUR MOST DEMANDING NEEDS

UNIQUE PROPERTIES

• Consistency of shape, hardness, size & smoothness

• Chemically inert

• High mechanical strength in high wear, impact resistance, and low dust

• Outstanding elasticity provides a high impact energy

• Available in coarse, fine and very fine sizes

CUTTING EDGE PERFORMANCE

• No contamination or damage to treated parts

• Consistent results from your first part to the last

• Cost-effective compared to low cost media

• Outstanding fatigue results with ceramic beads

• Smooth satin surface finish obtained with ceramic beads

• Excellent surface etching with ceramic grits

• Enhanced performance in dry air blast, wet blast and wheel blast systems

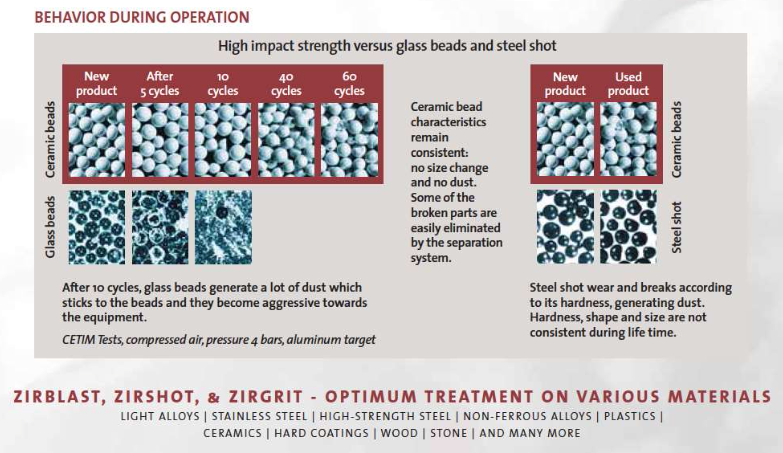

BEHAVIOR DURING OPERATION

High impact strength versus glass beads and steel shot

MEET YOUR MOST DEMANDING NEEDS

UNIQUE PROPERTIES

• Consistency of shape, hardness, size & smoothness

• Chemically inert

• High mechanical strength in high wear, impact resistance, and low dust

• Outstanding elasticity provides a high impact energy

• Available in coarse, fine and very fine sizes

CUTTING EDGE PERFORMANCE

• No contamination or damage to treated parts

• Consistent results from your first part to the last

• Cost-effective compared to low cost media

• Outstanding fatigue results with ceramic beads

• Smooth satin surface finish obtained with ceramic beads

• Excellent surface etching with ceramic grits

• Enhanced performance in dry air blast, wet blast and wheel blast systems

BEHAVIOR DURING OPERATION

High impact strength versus glass beads and steel shot

STAINLESS STEEL ABRASIVES

AREAS OF APPLICATION:

• Blast cleaning, de-burring, surface refinement, surface finishing

• All types of aluminum castings and forgings

• Zinc pressure die castings

• Non-ferrous metals and special alloys

• Stainless steel castings and forgings

• Stainless steel equipment fabrication

• Granite and stone industry CHRONITAL offers the following advantages:

• Greater durability

• Shorter blasting times

• Brighter finish

• Rust-free surfaces

• Reduced wear on machines

BLASTING OF METAL:

• for effective de-burring

• short blasting times

• perfect surface finish

• Rust-free surfaces

10 Sizes are available

Call for Pricing

Cast stainless abrasive, rust-proof spherical

Chemical Analysis:

C ~ 0.17%, Cr ~ 0.18%, Ni ~ 10%,

Si ~ 1.8%, Mn ~ 1.2%

• Blast cleaning, de-burring, surface refinement, surface finishing

• All types of aluminum castings and forgings

• Zinc pressure die castings

• Non-ferrous metals and special alloys

• Stainless steel castings and forgings

• Stainless steel equipment fabrication

• Granite and stone industry CHRONITAL offers the following advantages:

• Greater durability

• Shorter blasting times

• Brighter finish

• Rust-free surfaces

• Reduced wear on machines

BLASTING OF METAL:

• for effective de-burring

• short blasting times

• perfect surface finish

• Rust-free surfaces

10 Sizes are available

Call for Pricing

Cast stainless abrasive, rust-proof spherical

Chemical Analysis:

C ~ 0.17%, Cr ~ 0.18%, Ni ~ 10%,

Si ~ 1.8%, Mn ~ 1.2%

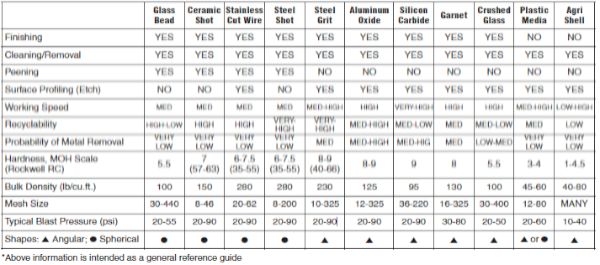

:: RECOVERABLE BLASTING MEDIA

RECOVERABLE BLASTING MEDIA

SPHERICAL SHAPED MEDIA

Ceramic Beads

Glass Beads

Stainless Shot

Steel Shot

Glass Beads

Stainless Shot

Steel Shot

ANGULAR SHAPED MEDIA

Aluminum Oxide

Ceramic Grit

Crushed Glass

Garnet

Plastic

Ceramic Grit

Crushed Glass

Garnet

Plastic

ANGULAR SHAPED MEDIA

Silicone Carbide

Stainless Grit

Steel Grit

Walnut Shells

Stainless Grit

Steel Grit

Walnut Shells

GENERAL MEDIA INFORMATION

• Spherical Medias are used for peening and produce smoother surface finishes.

• Angular medias chip at a parts surface removing paint, rust, and scale quicker than round medias and produce a rougher surface finish and better anchor patterns for coating adhesions.

• Higher blast pressures reduce media life.

• Higher blast pressures increase production.

• Angular medias chip at a parts surface removing paint, rust, and scale quicker than round medias and produce a rougher surface finish and better anchor patterns for coating adhesions.

• Higher blast pressures reduce media life.

• Higher blast pressures increase production.

• Harder work pieces reduce media life.

• Dust collection keeps media clean.

When calculating media take into account:

• Media cost and life cycles

• Disposal fees (if blasting heavy metals use a very recyclable media)

• Production rate of media, labor and air compressor expense.

• Dust collection keeps media clean.

When calculating media take into account:

• Media cost and life cycles

• Disposal fees (if blasting heavy metals use a very recyclable media)

• Production rate of media, labor and air compressor expense.

MEDIA BLASTING COST

Media Cost Per Hour

Hourly Delivery Rate X % Breakdown

X Cost Per Lb.

Media Cost to Blast a Part

Hourly Delivery Rate X % Breakdown

X Cost Per Lb. X

Part cycle time (% of Hour)

Hourly Delivery Rate X % Breakdown

X Cost Per Lb.

Media Cost to Blast a Part

Hourly Delivery Rate X % Breakdown

X Cost Per Lb. X

Part cycle time (% of Hour)

MEDIA LIFE

Silica Sand

Garnet

Plastic Media Glass beads

Silicone carbide

Aluminum oxide

Ceramic media

Steel shot, grit

Stainless shot, grit

Silica Sand

Garnet

Plastic Media Glass beads

Silicone carbide

Aluminum oxide

Ceramic media

Steel shot, grit

Stainless shot, grit

CYCLES

1

3-5

7-9

9-12

9-10

10-12

70-90

80-100

150-225

1

3-5

7-9

9-12

9-10

10-12

70-90

80-100

150-225

% BREAKDOWN

100%

25%

13%

10%

11%

9%

1.2%

1%

.5%

100%

25%

13%

10%

11%

9%

1.2%

1%

.5%

BLAST SPECIFICATIONS

ESTIMATED BLAST CLEANING RATES#1 WHITE METAL BLAST

Approx. Sq. Ft. Cleaning

Per Hour at 90

Approx. Sq. Ft. Cleaning

Per Hour at 90

#7 NOZZLE

Tight Mill Scale 140 Sq. Ft.

Layered Paint 70 Sq. Ft.

Tight Mill Scale 140 Sq. Ft.

Layered Paint 70 Sq. Ft.

SSPC-SP5

Loose Mill Scale 170 Sq. Ft.

Pitted Paint 85 Sq. Ft.

Loose Mill Scale 170 Sq. Ft.

Pitted Paint 85 Sq. Ft.

#2 NEAR METAL BLAST

Approx. Sq. Ft. Cleaning

Per Hour at 90

Approx. Sq. Ft. Cleaning

Per Hour at 90

#7 NOZZLE

Tight Mill Scale 146 Sq. Ft.

Layered Paint 72 Sq. Ft.

Tight Mill Scale 146 Sq. Ft.

Layered Paint 72 Sq. Ft.

SSPC-SP10

Loose Mill Scale 180 Sq. Ft.

Pitted Paint 90 Sq. Ft.

Loose Mill Scale 180 Sq. Ft.

Pitted Paint 90 Sq. Ft.

#3 COMMERCIAL METAL BLAST

Approx. Sq. Ft. Cleaning

Per Hour at 90

Approx. Sq. Ft. Cleaning

Per Hour at 90

#7 NOZZLE

Tight Mill Scale 270 Sq. Ft.

Layered Paint 140 Sq. Ft.

Tight Mill Scale 270 Sq. Ft.

Layered Paint 140 Sq. Ft.

SSPC-SP6

Loose Mill Scale 420 Sq. Ft.

Pitted Paint 200 Sq. Ft.

Loose Mill Scale 420 Sq. Ft.

Pitted Paint 200 Sq. Ft.

#4 BRUSH OFF

Approx. Sq. Ft. Cleaning

Per Hour at 90

Approx. Sq. Ft. Cleaning

Per Hour at 90

#7 NOZZLE

Tight Mill Scale 835 Sq. Ft.

Layered Paint 825 Sq. Ft.

Tight Mill Scale 835 Sq. Ft.

Layered Paint 825 Sq. Ft.

SSPC-SP7

Loose Mill Scale 840 Sq. Ft.

Pitted Paint 830 Sq. Ft.

Loose Mill Scale 840 Sq. Ft.

Pitted Paint 830 Sq. Ft.

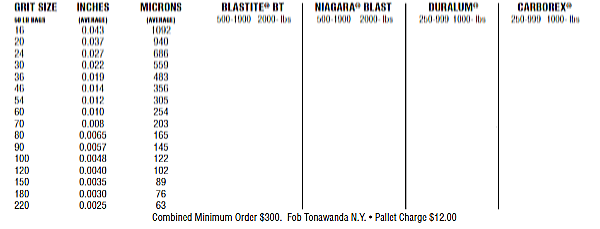

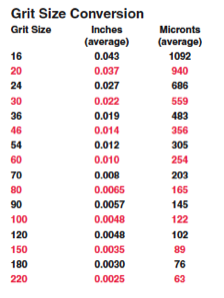

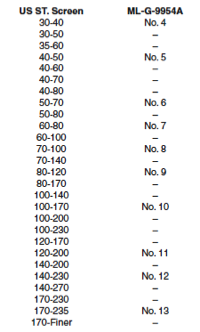

BLAST MEDIA SIZING INFORMATION

ALUMINUM OXIDE

GLASS BEADS

SHOT & GIRT